Bushfire performance of glazing in bushfire prone areas

By Engaged Expert

Alim RaselAlim is a Senior Fire Assessment Engineer based in Australia. He holds PhD in Mechanical Engineering and has excellent knowledge of local and international standards.

In this blog, Senior Fire Assessment Engineer, Alim Rasel explores the difference glazing can make to a residential and commercial buildings bushfire resistance.

Over the years, glazing has grown in popularity in residential and commercial buildings. Glass offers an extraordinary level of transparency that can brighten up a building's space. It also adds to the uniqueness of a construction which helps them stand out. In addition to its aesthetics, glass is highly recyclable and cost-effective.

Glass is versatile and manufactured to meet specific applications within construction. The main types of glass include:

- Laminated glass, which is glass that comprises multiple thin layers, making it more resistant to impacts

- Toughened glass, which is glass that undergoes a special manufacturing process and contains inert components, giving it superior strength

- Floating glass, which is produced in a variety of colors to enhance the aesthetic appeal of a building

- Tinted glass, which is designed to absorb UV rays and provide privacy.

The importance of getting glazing right for bushfire resistance

In areas prone to bushfires, it is crucial to ensure that buildings incorporating glazing maintain adequate fire hazard properties to withstand the intense radiant heat and ember attack.

Typically, glass is installed on a steel or timber frame. Once the glass is exposed to radiant heat, the exposed side heats up - which leads to a thermal gradient across the thickness of the pane. The thermal gradient imparts thermal stress on the material, which is primarily distributed in the central region of the pane. The frame somewhat shields the edges and the rims and remains relatively cooler. This means the central area expands while the edges stay in place. This shift in the thermal gradient causes the glass to break. Glass can also crack at the edges due to a large thermal gradient between the embedded glass in the frame and the exposed glass.

In addition to this, failure can also occur due to other glazing components. Several studies have shown that variables such as glass type, frame material, and fixings are vital in bushfire performance. For example, insulated and laminated glass is likely to offer superior bushfire performance compared to single, non-insulated glass.

Key performance factors in glass

The key performance factors in the insulated glass were reported to be the air gap and fireside pane size. In the case of laminated glass, the interlayer gel was reported to be crucial in limiting shattering and gap formation. Thicker glass and frames generally perform better than their thinner counterparts.

Apart from thickness, the construction of the frame is also crucial. The more combustibles are introduced - seals, gaskets etc. - the less likely the structure will perform well under a bushfire attack. The nature of the fixing has also been observed to influence the glazing's performance.

For example, point fixing introduces weak points prone to premature failure.

Bushfire Attack Levels

AS 3959:2018[1] stipulates the construction requirements for buildings located in bushfire-prone areas. These requirements are categorised based on the level of expected radiant heat exposure.

They are:

- BAL LOW

- BAL 12.5

- BAL 19

- BAL 29

- BAL 40

- BAL FZ.

Each Bushfire Attack Level, or BAL, represents a predicted level of bushfire attack. You must assess the applicable BAL for any building construction - as specified in section 2 of AS 3959:2018. Sections 5.5, 6.5, 7.5, 8.5 and 9.5 of AS 3959 stipulate the construction requirements for external glazing in BAL 12.5, BAL 19, BAL 29, BAL 40 and BAL FZ exposures. These stipulations relate to additional screens or shutters, frame material, hardware, glazing, seals and weather strips.

As the BAL exposure increases, the requirements become more stringent. For example, under BAL 12.5, bushfire shutters protecting windows and doors can be made of either:

- Non-combustible material

- A timber species specified in Paragraph E1 of Appendix E

- Bushfire-resisting timber

- Or any combination of the above.

In contrast, under BAL 40, shutters can only be made of non-combustible materials.

Likewise, the frame material for windows and sidelights under BAL 12.5 can be made of either:

- Bushfire-resisting timber

- A timber species specified in Paragraph E1 of Appendix E

- Metal or metal-reinforced uPVC.

Under BAL 40, the frame must strictly be constructed of metal.

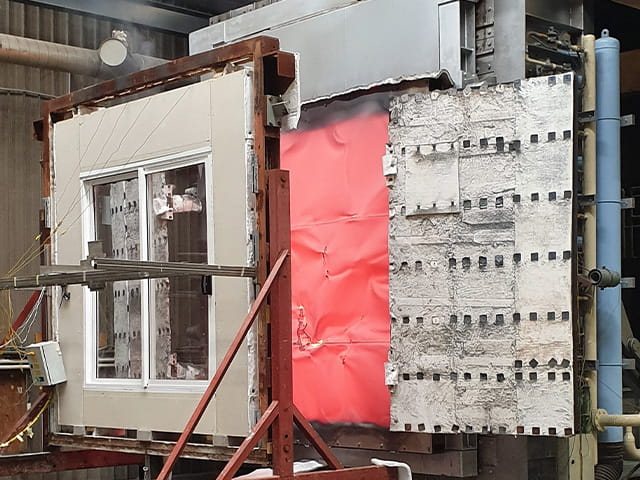

In addition to the requirements of AS 3959:2018 in sections 5.5, 6.5, 7.5, 8.5 and 9.5, any novel glazing system that satisfies the test criteria of AS 1530.8.1:2018[2] (from BAL 12.5 to BAL 40) or AS 1530.8.2:2018[3] (BAL FZ) can be used.

This satisfaction of the test criteria makes the guideline in AS 3959:2018 dynamic. As construction is not rigidly restricted to the standard's requirements, new systems can be introduced if they demonstrate satisfactory performance.

What's next for the glazing industry and bushfire requirements?

Given the popularity of glazing, the industry is adapting to bushfire requirements by offering products that strictly adhere to the requirements of AS 3959:2018. New and innovative products are also taking advantage of the pathway through AS 1530.8.1:2018 or AS 1530.8.2:2018. Some of these innovations include reinforcing frames, incorporating additional protection such as seals, gaskets, intumescent materials, or mineral wools within the frames, and enhancing the strength of the glass by introducing features like air gaps, inert gases, or intumescent layers. Through careful planning, it is possible to develop durable and robust constructions that significantly reduce the risk of house loss during a bushfire while maintaining an aesthetically pleasing design.

Notes:

[1] Standards Australia, 2018, Construction of buildings in bushfire-prone areas, AS 3959:2018, Standards Australia, NSW.

[2] Standards Australia, 2018, Methods for fire tests on building materials, components and structures – Part 8.1: Tests on elements of construction for buildings exposed to simulated bushfire attack - Radiant heat and small flaming sources, AS 1530.8.1:2018, Standards Australia, NSW.

[3] Standards Australia, 2018, Methods for fire tests on building materials, components and structures – Part 8.2: Tests on elements of construction for buildings exposed to simulated bushfire attack - Large flaming sources, AS 1530.8.2:2018, Standards Australia, NSW.

Find related Resources