Fire Resistance Testing

Warringtonfire are a global leader in fire resistance testing for construction, furniture, marine and rail sectors and specialize in testing passive fire protection products including fire doors, structural steelwork protection, fire stopping products and large-scale testing of cladding. We offer independent, locally accredited fire resistance testing services for passive fire protection products for both commercial and domestic building types. Our fire resistance testing is done to British, European, International standards, in line with CE marking, UKCA and UKNI marking and third-party certification. We undertake this fire resistance testing from our UKAS accredited testing facilities in Warrington, High Wycombe and Dubai, as well as our BELAC accredited testing facility in Gent.

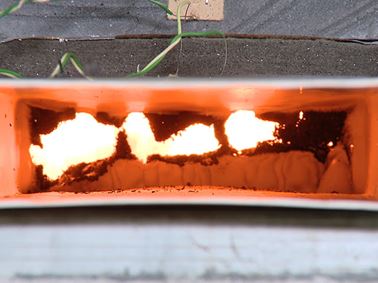

What is Fire Resistance Testing?

Fire resistance can be determined through destructive fire testing, designed to replicate the product’s intended end-use. The specimen to be tested is built into an appropriate supporting construction within a restraint frame and mounted onto a front of a furnace. The temperature within the furnace is controlled according to an internationally accepted time/temperature regime.

Products we can test for Fire Resistance

Our fire resistance testing includes the following products: building materials, doors and shutter assemblies, ducts, dampers, cable trays, floors, glazing, pipes and penetrations, intumescent paint, intumescent seals, load bearing and non-load bearing elements, suspended ceilings, walls and partitions.

Our fire resistance testing capabilities are:

Our Services

SERVICES

Doorsets and Hardware Testing

Find out about our full range of accredited door fire testing services and fire resistance testing for door hardware (such as locks, latches, hinges, closers, exit devices and kick plates).

Duct Testing

Find out about our fire resistance duct testing capabilities available from our BELAC accredited laboratory in Gent.

Fire Stopping Product Testing

Find out about our UKAS and BELAC accredited fire stopping product testing services designed to meet British, European and International standards.

Floor and Suspended Ceilings

Warringtonfire can provide reaction to fire, combustibility, as well as fire resistance, testing for all your floor and suspended ceiling system requirements

Glass and Glazing Systems Testing

Find out about our UKAS and BELAC accredited glass and glazing systems fire testing services designed to meet British, European and International standards.

One Site One Solution Testing Services

Save time, reduce costs and increase market access by using our UKAS accredited testing laboratory in High Wycombe UK for acoustic, smoke and fire testing.

Smoke Curtains and Components

Learn how Warringtonfire’s smoke curtain testing to various standards, including BS and EN, can help you meet building regulations requirements.

Smoke Leakage Testing

Find out about our smoke leakage testing services (to EN 1634 Part 3, BS 476 Part 31.1 and AS 1530.7), for door and shutter assemblies, openable windows and other elements of building hardware.

Structural Steelwork Protection Testing

Find out how our team of engaged experts can work with you to create a design-led, cost-effective structural steelwork protection test programme with on-going support.

Wall and Partition Systems Testing

Find out how we perform accredited walls and partitions fire resistance testing to British, European and International standards.